Stamped Concrete Pro's & Con's

Stamped Concrete Pro's & Con's

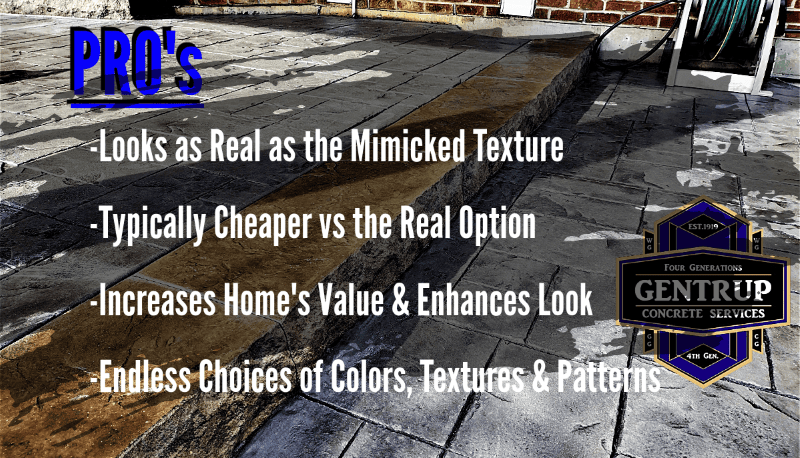

Stamped Concrete Pros:

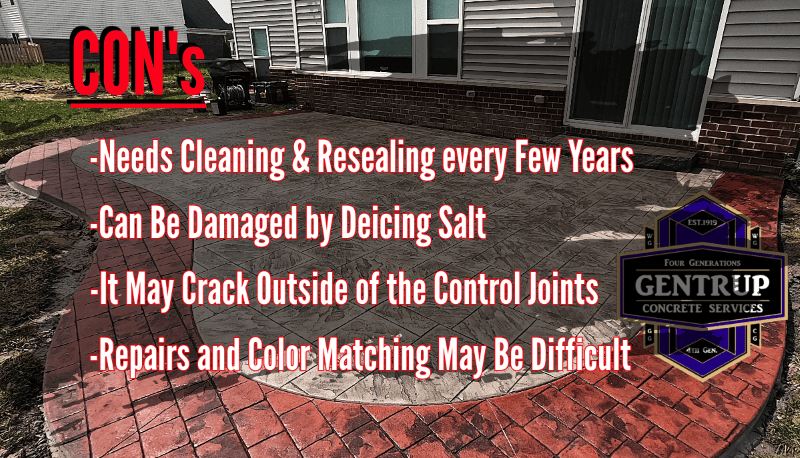

Stamped Concrete Cons:

Stamped Concrete Process

Stamped Concrete Process

Stamped Concrete Basics

Concrete Placement: The to-be-poured area will be prepared and formed for the new concrete. A specific stamp concrete mix will be provided by a concrete plant. Typically an integral color is added to the concrete at the plant to achieve the desired base color. The wet concrete is then poured into the prepared area, flatten and smoothed.

Coloring: There are two main forms of coloring practice's for stamped concrete, integral and color hardener.

-Integral Color is added to the concrete truck before it leaves the plant. This color will encompass the concrete completely from top to bottom and side to side.

-Color Hardener is a powder throw over the wet, normal colored concrete after in has been poured. Color hardener only colors the top layer of your concrete.

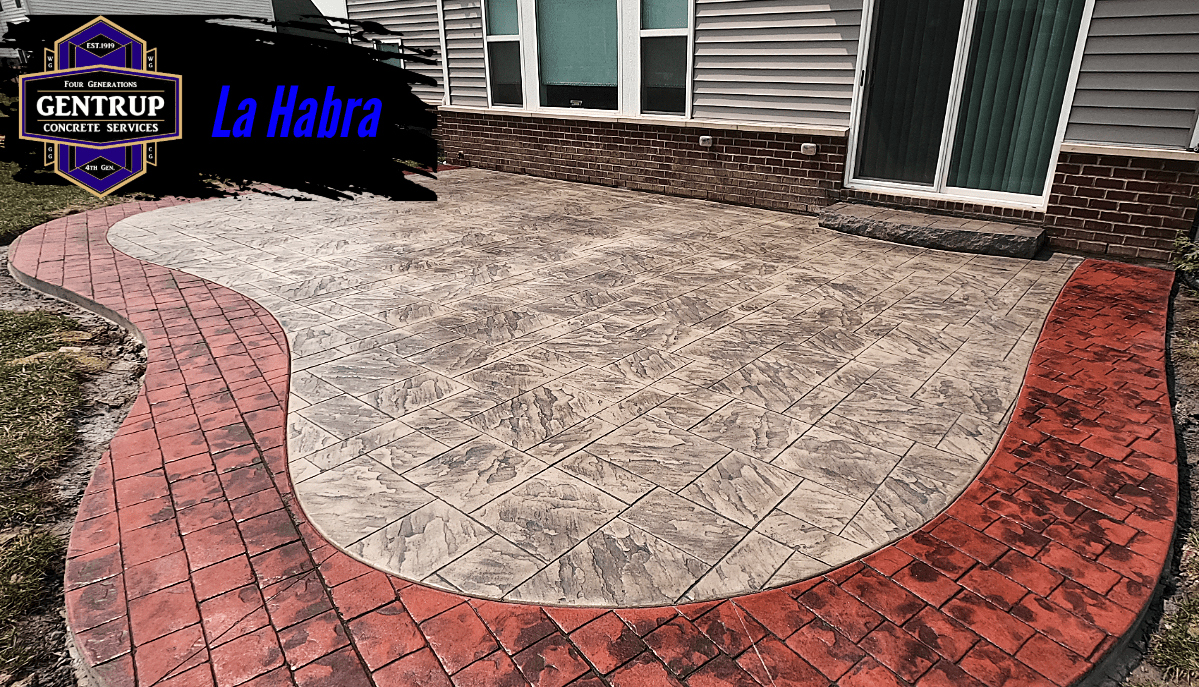

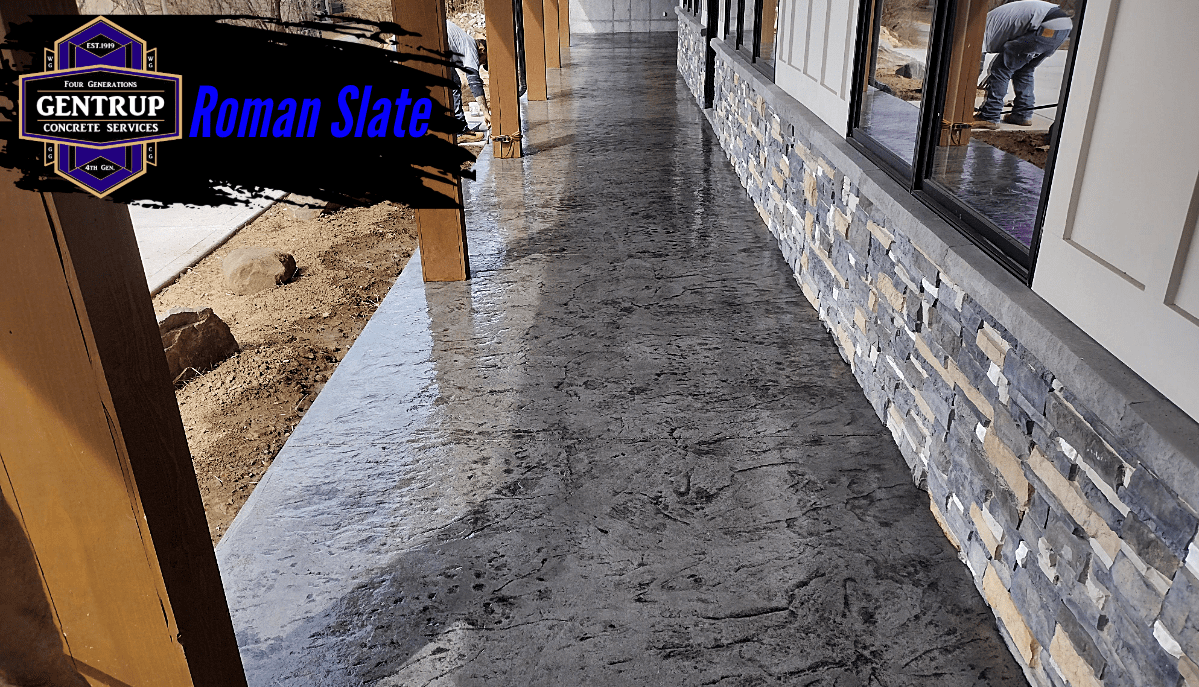

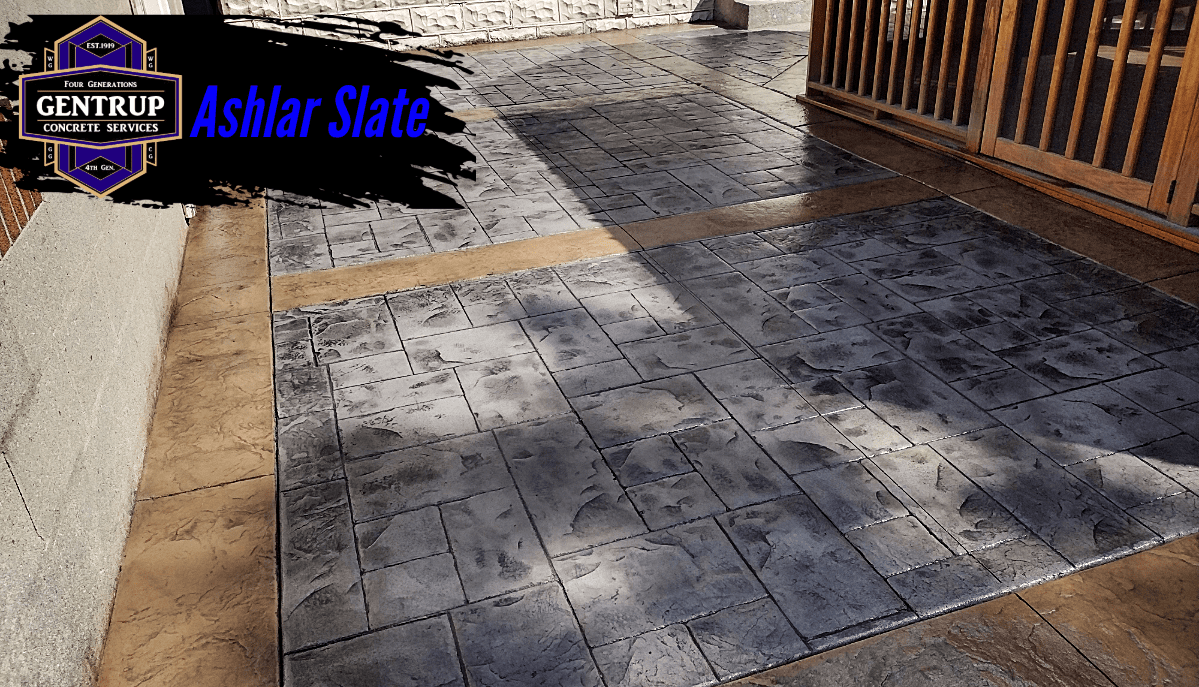

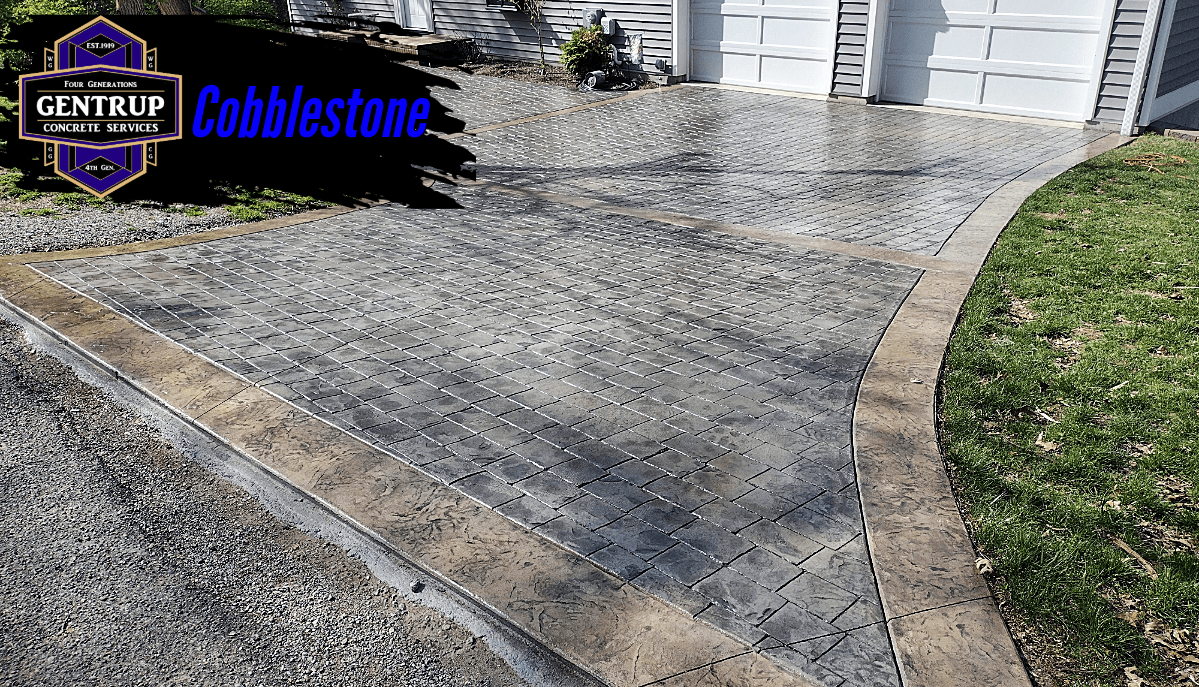

More detail regarding color terms, usage and color variations can be found on our Colors Page.Stamping Tools: Specialized rubber or polyurethane mats with intricate patterns and textures are provided by the contractor. The texture is typically selected by the homeowner before the work begins. There are 100's of textures. Typically concrete contractors own the stamp sets commonly requested, other texture sets can usually be rented from a local material provider(we use Deco-Crete Supply).

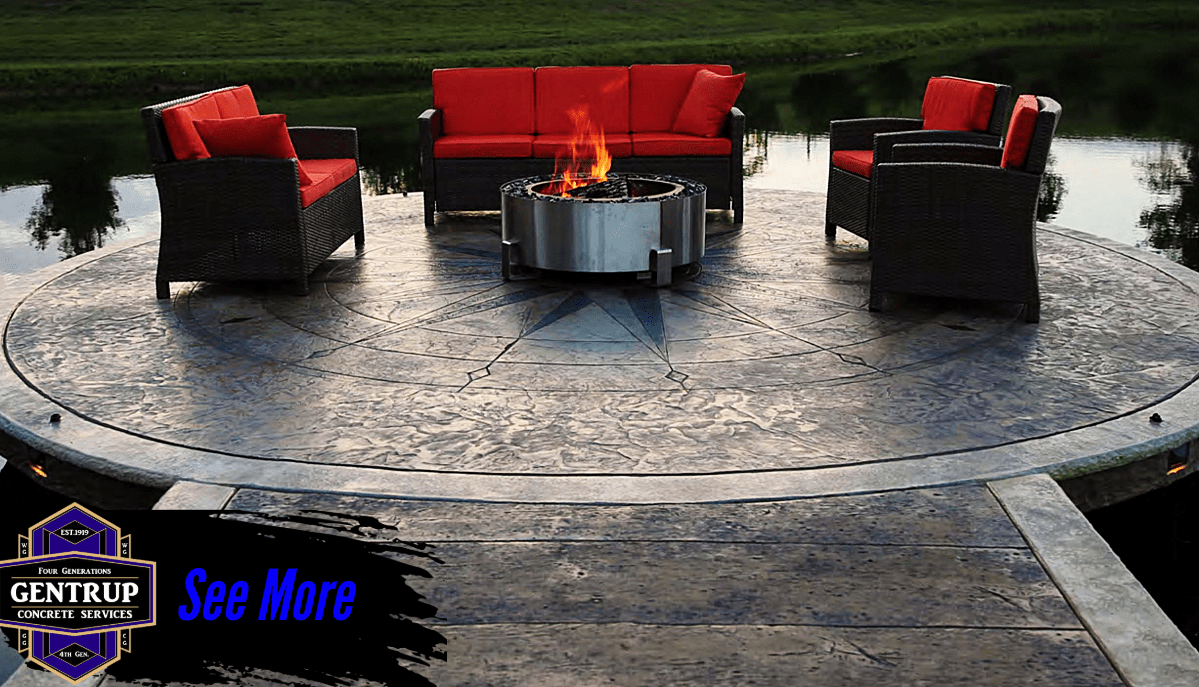

Stamping Process: While the concrete is still in its plastic or semi-liquid state, the stamps are pressed onto the surface one by one. This is usually done in a particular sequence, so the patterns align seamlessly. This requires skill and precision to avoid duplication, gaps or other pattern and texture issues.

Release Agents: To prevent the stamps from sticking to the wet concrete paste, a release agent or bond-breaker will need to be applied. There are several bond breakers commonly used. Liquid Release, also known as a bubblegum release is one option. The second and better option is a color powder release. Typically, this color will be chosen to add contrast to the base color(s). The powder release color will pressed into the depressions & lowers textures of the stamp when the rubber mat is tamped.

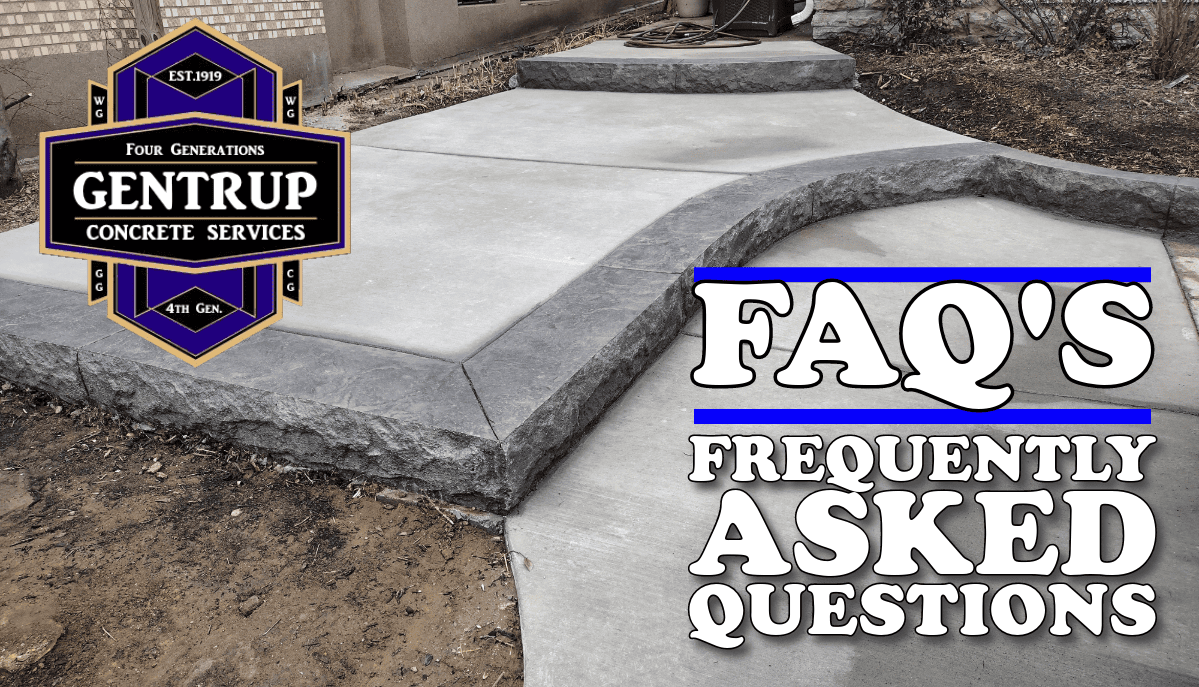

Control Joints: Crack control joints are saw cut into the concrete to predict and hide where the concrete will crack(concrete always cracks - see concrete FAQ's). Sometimes the joints are cut into the wet concrete. This is very common for normal concrete, less common for stamped concrete.

Cleaning & Detailing: The stamped concrete is allowed to cure/harden for a period of time, typically a day or two. Normally, a pressure washer & broom are used to clean the release agent off the concrete. Sometimes a soap or light muriatic acid are also used. This is especially important if a powder release color was used. This will remove 80%-90% of the color release from the new concrete. Leaving just secondary color in the lower depressions, creating a realistic 3-D look. Detailing of any imperfections in the stamp is typically done at this time.

Sealing: After the concrete has had time to dry and cure, a sealer is then applied. This sealer enhances the color(s), provides protection against wear & tear, and makes the surface easier to clean. For stamped concrete we typically suggest and use a high-quality, oil based sealer. That said, not all sealers are the same. For example, certain big box stores sell oil-based concrete/decorative concrete sealers. We've found that these sealers are extremely harmful to stamped concrete. If used, you MUST cut the sealer heavily. Otherwise the sealer may cause delamination of the concrete's surface/colors. We suggest using Gem-Seal 400 from Brickform, or our favorite sealer, D1 Concrete Sealer from Deco-Crete Supply.

Stamp Concrete Terms

Stamp Concrete Terms

Stamp Concrete Terms

Basic Terms to Know Regarding Stamped Concrete:

"Main Color" - This color represents the primary hue of your concrete. Essentially, your concrete will predominantly exhibit this color, with accents of a secondary color (powder release) in the low points and depressions, which will be elaborated on below. There are two main types of primary colors: "Integral" and "Color Hardener." Color hardener typically offers a wider range of color options but entails more labor as the color needs to be applied to the wet concrete and worked in (resulting in higher costs). Integral color, on the other hand, is added at the concrete plant and transported in the concrete truck. This method necessitates less labor, creates less mess, and ensures color consistency. Occasionally we use an Integral color and throw spots of Color Hardener(s) on top - adding more shades to the main color.

"Liquid Release" - Liquid release is a transparent liquid sprayed on the wet concrete to create a bond-breaker for the rubber stamps. Liquid release, also know as "bubblegum release" does not introduce any additional color. This results in a concrete stamp that appears one-dimensional, lacking the depth and texture mimicking stone, brick, or other materials the stamp aims to replicate. Typically, we avoid using liquid release as it will not achieve our desired realistic appearance and often just looks fake. It's worth noting that a secondary color can be applied later, but it never looks as real, and isn't as permanent as "Powder Release". Liquid release can be a viable option if you seek something more than regular concrete while working within a tight budget.

When discussing your project with your contractor, be sure to inquire about the type of "Release" being used, as it significantly impacts the overall cost. If your contractor ISN'T utilizing powder release, ensure they have plans to incorporate a SECONDARY ANTIQUE COLOR to achieve the best, most realistic results.

"Oil-Based Sealer" - The colors and textures of decorative concrete are significantly enhanced by applying multiple, light coats, of the right quality oil-based sealer to the new concrete. In addition to enhancing aesthetics, this process helps protect the concrete and its colors. Periodic cleaning, re-sealing, or rejuvenation of the concrete will be necessary every few years to maintain its appearance and protection. Done correctly, this maintenance process will restore the concrete to its original new-like appearance. Learn more about concrete sealing below.

Integral Color vs Color Hardener

Liquid vs Powder Release

Stamped Concrete Upkeep

Stamped Concrete Upkeep

Check for Concrete Sealer

Test with water: If the water soaks into the concrete, then it's unsealed. If the water beads up and/or puddles on top of the concrete, then it's sealed. Please watch the video below for a demonstration.

Reviving Your Concrete's Colors.

Does your concrete still have sealer on it? Then buy rejuvenate from Deco-Crete Supply and follow this video's instructions.

Little or No Concrete Sealer Left?

No sealer? Then it's time to re-seal your stamped concrete. Follow these steps carefully:

- Thoroughly clean and pressure wash the concrete.

- Use a blower to remove any standing water and to clear water from the joints and cracks. Allow 24 hours or more for drying – this step is crucial. The concrete must be completely dry, with no moisture in the concrete's small pores, joints, cracks or on the surface.

- Purchase a sprayer and a high-quality sealer such as Gem Seal 400 or D1 Concrete Sealer from Deco-Crete Supply.

- Follow the instructions provided in the video below.

Watch the video for detailed instructions. We cannot stress enough to use one of the mentioned sealers and allow for 24 hours or more before sealing. Failure to do so may lead to costly problems for your decorative concrete.

Lastly, never use any kind of ice/snow melting product on stamped concrete, or really any type of concrete. These products will more than likely damage your concrete to some degree, regardless of what the manufacturer says. If you see any kind of spotting, hazing, spalling and/or blemishes on your stamped concrete it's best to contact your contractor immediately.

Please feel free to contact us with any other questions regarding decorative concrete sealing. Special thanks to our friends at Deco-Crete Supply for the video tutorials.

Conclusion:

Conclusion:

To get the full effect of stamped concrete, you should make sure your contractor is using a main color, a secondary color & a quality oil based sealer(several light coats). Stamped concrete is expensive! If a bid is significantly lower than the others, find out why before you sign the contract! There are different techniques to the process. Cheaper options can leave your texture dull, one dimensional and colorless. Gentrup Concrete's preferred process provides multiple colors, definition and a long-lasting, realistic and beautiful finished product.

Oh, and make sure you have a contract! Our contracts are thorough and ensure both party's are protected. See our example contract here.